Onsite disposal of Effluent and Wastewater

All properties where wastewater is produced must be connected to an approved drain or system for the treatment of wastewater and effluent.

On-site effluent disposal systems are not accepted as an alternative to sewer if it available to the property (within 90m), however in areas where main sewer is not available, an on-site effluent disposal system must to be installed. To check if a property is connected or can be connected to sewer please contact the Water Corporation on 13 13 95. You can also check if a connection may be available on the water corporations property search.

There are a variety of systems available which range from:

- conventional primary treatment systems (septic tanks and leach drains),

- secondary treatment units known as Aerobic Treatment Units (ATUs)

- greywater re-use systems

- Waterless composting toilets

Any system that is to be installed and used must be a type approved by the Department of Health WA and have the Local Governments approval. Please check the Department of Health WA: WA Approved effluent and wastewater systems

Septic Systems

Septic systems (also known as primary treatment systems) are the most common and simplest systems used to treat and dispose of sewage (also called wastewater) where a sewer connection is not available. Once in use septic systems must have their active drain switched every 6 months, should be checked every 1-2 years, and the solids in the system pumped as needed (usually every 4-10 years).

|

What they are:

Septic systems consist of two watertight tanks called septic tanks (or one larger tank separated into two chambers by a baffle) which are connected to one or two soakwells or drains which have holes in their sides and no base.

The septic tanks are designed to digest solid and liquid waste into an effluent which is discharged into the ground by the leach drains or soak wells.

|

|

How they work:

When wastewater passes through the septic tanks, heavier solids sink to the bottom and undergo bacterial digestion. This breaks down the solids and also changes it to sludge, which builds up in the bottom of the tank. Grease and oil float to the surface in the tanks to form a crust over the liquid. The remaining liquid, called effluent, undergoes bacteriolytic action which improves the quality and safety of the liquid. This effluent then flows from the tanks into the drains to be held and soak into the surrounding soil over time where it may undergo further natural treatment processes. The effluent may then naturally filter through the soil safely to drain away, evaporate and be absorbed by plants.

|

|

|

Materials:

The most common type of septic system are precast concrete septic tanks connected to two precast concrete leach drains. There are however a range of new products using other materials which have also been approved for use by the Department of Health WA. Contractors and installers may opt for plastic drains or flatbed drain systems which may require more length due to their smaller size but can often be installed without heavy machinery.

WA Health approved premade leach drain manufacturers can be found here: Approved Leach Drains

Sizes:

Since 1989, most household septic tank systems have been installed with either two leach drains or two soak well sets. These are called alternating systems as they have a diverter box which can change the flow of effluent, allowing one half of the soak wells or one of the leach drains to be shut off at any time. This allows the unused portion to dry out which rejuvenates the soil’s ability to receive effluent.

Most soils in Toodyay vary from Gravels and Loams to clays with the majority of septic systems requiring drains between 9m and 14m with some amendments to the soil around the install area

The type of septic tank or leach drain system that can be used on a property depends on a number of things including:

- the number of potential occupants of a structure it connects to,

- the amount of space available (the land application area),

- depth of ground water,

- proximity to water bodies,

- nearby wetlands and winter creeks,

- the soil type,

- the contours of the land

Sites may need to be assessed individually by the Shire to determine if a septic system is appropriate effluent disposal system for the property.

|

Aerobic Treatment Units (ATUs)

Aerobic Treatment Units (ATU’s) are an alternative to conventional septic tanks and provide an improved quality of effluent treatment. ATUs use the processes of aeration and clarification to better treat wastewater producing an end product of a higher standard and safety. Due to their pumps and aerators ATUs legally must be maintained under a service contract and checked every 3 months.

ATUs are often used where a higher quality of effluent treatment is required due to site constraints or is desired by owners for more flexibility of wastewater use.

ATU systems can be capable of removing phosphate so some owners opt to use an ATU due to the environmental concerns associated with the degradation of environmental water bodies by the phosphates in wastewater where the soil has no capacity to absorb it. Some developments also have planning requirements to use a wastewater system that is capable of removing phosphates or treat effluent to a higher quality.

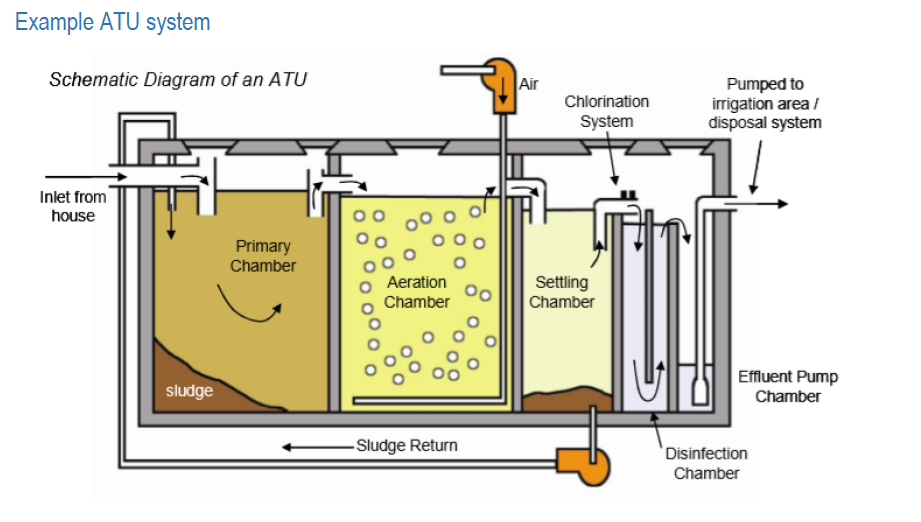

ATUs consist of a series of treatment chambers combined with an irrigation or drain disposal system. The first chamber is similar to a conventional septic tank in that the wastewater enters the chamber, the solids settle to the bottom where they undergo anaerobic digestion by bacteria and form a layer of sludge on the chamber floor. Scum (consisting of oils, grease, etc) floats to the surface of the liquid and the partially clarified wastewater flows into a second chamber. Here the liquid is mixed with air to assist bacteria to breakdown more of the finer organic material. A third chamber allows additional clarification by the settling of suspended solids (which are returned to the first chamber). The clarified effluent in the third chamber is of a high enough standard for it to be successfully disinfected, usually by chlorination, in a fourth chamber. Disinfection reduces the number of bacteria in the final effluent.

The higher quality treatment of the effluent allows the option of disposing effluent under mulch through a drip line or using some systems by spray irrigation. Whilst ATU effluent is treated to a higher standard than septic tank effluent and has undergone chlorination, it still has a small chance to contain pathogenic microorganisms, some of which are chlorine resistant so above ground disposal areas must have signs and be in areas that don't have food growing in them or casual access by animals.

ATUs are often required where:

A public water catchment is within 100m

A wetland is within 100m

There is a perched water table or rock hardpan

The property is less than 4000m² and has a light clay soil

The property is less than 2000m² and has a clay loam soil

Greywater Systems

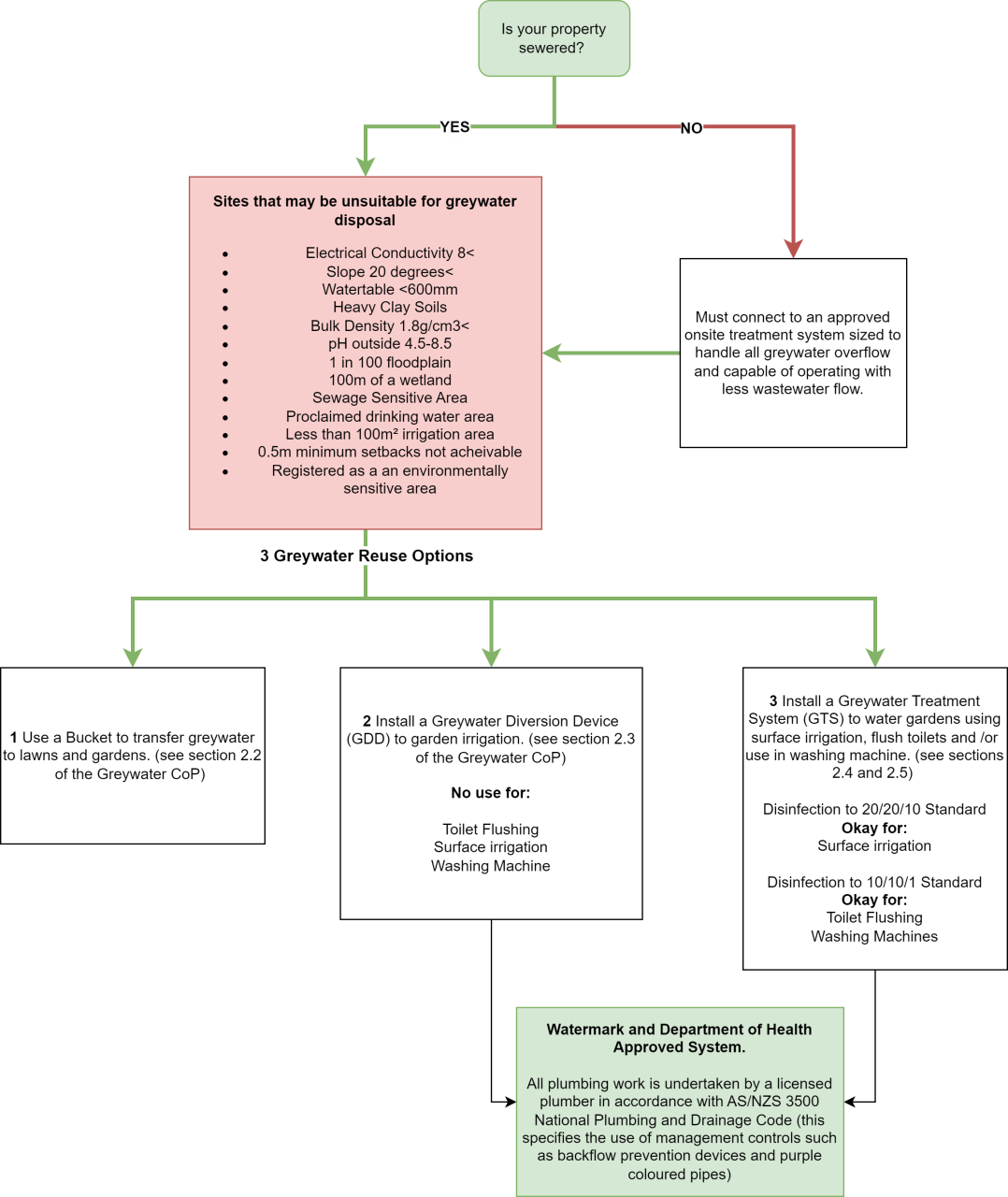

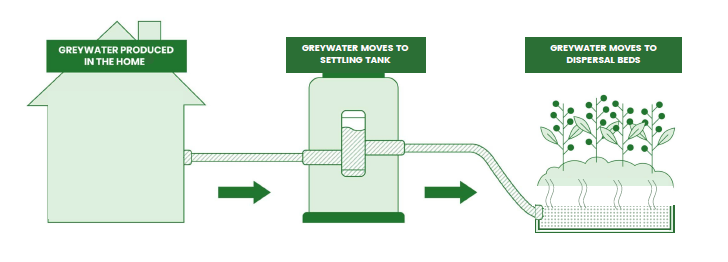

The opportunity exists for treated greywater to be reused for a number of end uses, such as irrigating gardens and flushing toilets. This reduces the demand on ground and rain water supplies and considering the sometimes limited supply of water, it is important that water is used efficiently and conserved wherever possible. Greywater systems are fantastic for properties on sewer. For areas not connected to sewer ATUs are often the better choice for water reuse garden irrigation and a well designed and placed septic system can keep a grassed area green.

Greywater systems however may improve the bacteriolytic quality of septic systems by removing chemicals and detergents from the system; this allows them to operate more efficiently. Certain greywater systems may also be plumbed to be used for toilet flushing.

There are two main greywater sources which are bathroom greywater (bath, basin, and shower) and laundry greywater. Kitchen wastewater can potentially be a source of greywater however it is usually heavily polluted with food, oils, detergents etc so it isn't suitable to use in all systems. Pathogenic microorganisms such as bacteria, protozoa, viruses and parasites can also be present in greywater in concentrations high enough to pose a health risk, so greywater reuse systems must be approved by the Department of Health and must irrigate the wastewater below ground unless a system that treats and disinfects is used.

Currently approved greywater systems

All Greywater systems must be installed and operated according to the WA Greywater Code of Practice

Waterless Composting Toilets

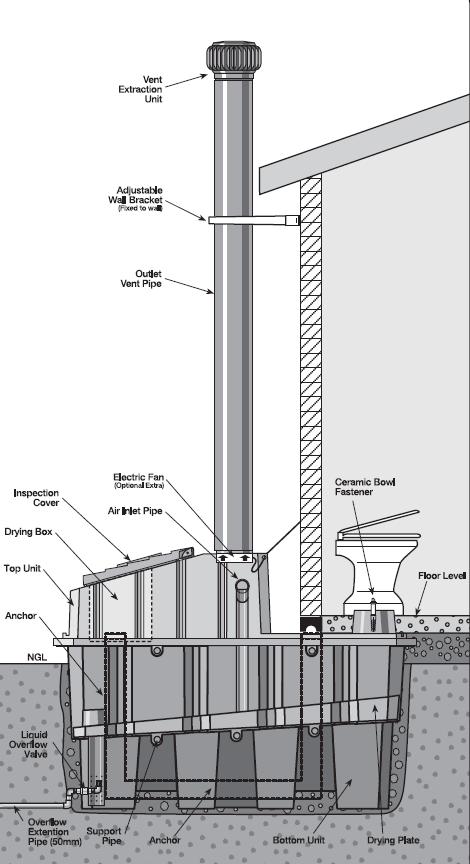

Waterless Composting Toilets rely on the principles of composting by microorganisms to decompose human waste, paper and other materials into an inoffensive and reasonably dry end-product that can be handled with minimum risk. They should not be confused with camping or chemical toilets.

|

A composting toilet is a well-ventilated container that provides the ideal environment for unsaturated human excrement and bulking material to undergo biological and physical decomposition under sanitary, controlled aerobic conditions.

Organic bulking materials are added through a hole in the top of the chamber to lower the moisture level, provide a source of carbon for good bacteria, as well as to keep the composting toilets contents porous for good aerobic conditions.

To get the best conditions for the microbiological breakdown processes the C:N (carbon to nitrogen) ratio of the compost should be around 30:1 and the moisture content around 12% to 40%.

Because the C:N ratio of excreta is less than 10:1 and it is extremely wet, bulking agents such as sawdust, husks, dried peat moss etc must be available to add in order to maintain the composting process.

Temperature and airflow also need to be carefully controlled to keep conditions favourable for composting. It is important that the airflow is enough to maintain aerobic conditions, remove any odours from anaerobic micro-sites in the compost pile, and remove the created carbon dioxide and water vapour. A warm temperature also keeps the bacteria active. The heat the bacteria produce is also one of the ways pathogens in the centre of the compost are killed. Good ventilation and temperatures are usually achieved in modern systems using an electric or solar fan and insulation.

|

As Waterless Composting Toilets require little to no water they can provide a solution to sanitation and environmental problems in unsewered rural areas. Not having flush toilets reduces water use by 10-60L a day and allows for the recycling of valuable plant nutrients on large properties. The lower water content of the compost is actually one of the critical components that needs to be maintained to ensure efficient and odourless operation, but some moisture is required as the composting process needs liquid for the microbes to survive. Too much moisture creates an anaerobic environment which slows the composting process and creates odours and encourages mould growth.

It is important to know that the WA code of practice for greywater requires a minimum 1800L sedimentation tank and appropriate drain for kitchen, laundry and bathroom greywater be installed with composting toilets. Greywater system is normally required to divert to sewer or onsite treatment systems in case of failure but can't do this when a waterless composting toilet is used.

Handling raw waste has historically been a problem so these systems are not suitable everywhere and require good management.

Not all pathogens are destroyed early in the composting process, so appropriate handling and disposal of the compost by owners is essential and the systems can't be installed everywhere. Waterless Composting Toilets can only be installed on single occupancy properties where there is adequate free space available to dispose of the compost without contaminating the site or impacting neighbouring land. Waterless Composting Toilets should also not be used in the urban areas, small block sizes, and locations with potential health risks associated with disposal.

Maintenance of composting toilet systems require more responsibility and commitment by users and owners than conventional wastewater systems and a properly maintained composting area. Faecal coliforms, salmonella and Vibrio cholerae can survive in soils 50-120 days after the composting process has begun. Helminth (worm) eggs can also survive many months. This makes it important for owners to minimise contact with the compost material and dispose of it correctly. New builders should also consider the narrower resale market they may face due to the extra management involved in these systems.

Most WA Health department approved systems require compost to be stored for 6 months and then be buried under 300mm of cover. It is important owners have a disposal area away from any edible plants, animal access, and areas which flood or have regular water flow. Depending on the system, site characteristics, health approvals, and usage an available disposal area may require more than 15m² per person per year in an approved location that is adequately far and shielded from property boundaries and dwellings.

Systems approved for use in WA can be found on the WA Department of Health website Approved composting toilets